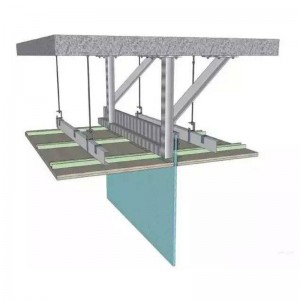

Fire-resistant Glass Hang Wall (Borosilicate Float Glass 4.0)

Product introduction

Borosilicate glass is a kind of float glass produced by float process with sodium oxide, boron oxide and silicon dioxide as basic components. This kind of glass has a high content of borosilicate, so it is called borosilicate glass.

Glass is required to have excellent stability when used as the fire-resistant glass partition.The fire resistance stability of this glass is currently the best among all fireproof glass, and the stable fire resistance duration can reach 120 min (E120).

Moreover, borosilicate glass also has high transmittance at high temperatures.This function is critical in case of fire and poor visibility. It can save lives when evacuating from buildings. High light transmittance and excellent color reproduction mean that it can still look beautiful and fashionable while ensuring safety.

Advantages

• Fire protection duration exceeding 2 hours

• Excellent ability at thermal shack

• Higher softening point

• Without self-explosion

• Perfect in visual effect

Application scene

More and more countries require doors and windows in high-rise buildings to have fire protection functions to prevent people from being too late to evacuate in the event of a fire.

Actual measured parameters of triumph borosilicate glass (for reference).

Thickness Processing

The thickness of the glass ranges from 4.0mm to 12mm, and the maximum size can reach 4800mm×2440mm(The biggest size in the world).

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc.

Our factory is equipped with internationally renowned equipment and can provide subsequent processing services such as cutting, edge grinding, and tempering.

Package and transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.