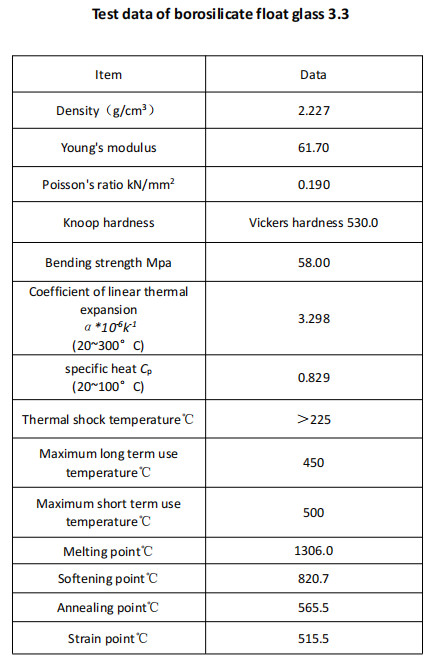

For High Quality, Durable Borosilicate Float Glass 3.3: Perfect Semiconductor Chip

Product Introduction

The main characteristics of high borosilicate glass 3.3 are: no peeling, non-toxic, tasteless; Good transparency, clean and beautiful appearance, good barrier, breathable, high borosilicate glass material, has the advantages of high temperature resistance, freezing resistance, pressure resistance, cleaning resistance, not only can be high temperature bacteria, can also be stored at low temperature. High borosilicate glass is also known as hard glass, is an advanced process made of processing.

Borosilicate glass 3.3 is a type of specialized glass that is used for many industrial and scientific applications. It has greater thermal shock resistance than ordinary glass, allowing it to be used in many different applications such as laboratory equipment, medical devices, and semiconductor chips. Borosilicate glass 3.3 also offers superior chemical durability and optical clarity compared to other types of glasses.

Characteristics

Outstanding thermal resistance

Exceptionally high transparency

High chemical durability

Excellent mechanical strength

Advantages

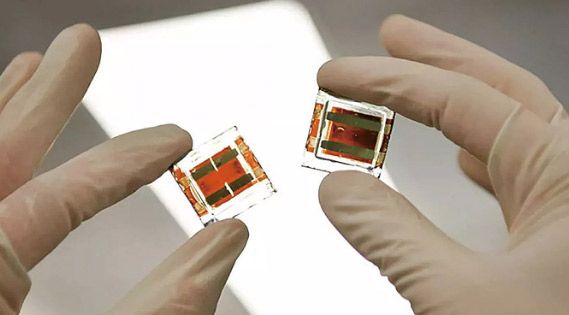

When it comes to the use of borosilicate glass semiconductor chip technology, there are many advantages to this material over traditional silicon-based chips.

1.Borosilicate can handle higher temperatures without its properties becoming affected by heat or pressure changes like silicon would when exposed to extreme conditions. This makes them ideal for high-temperature electronics as well as other products requiring precise temperature control—such as certain types of lasers or x-ray machines where accuracy needs to be paramount due to the potentially dangerous nature of the radiation they emit if not properly contained within their housing materials.

2.Borosilicate’s remarkable strength means that these chips can be made much thinner than those using silicon wafers – a major plus for any device needing miniaturization capabilities such as smartphones or tablets with very limited space inside them for components like processors or memory modules which require large amounts power yet have low volume requirements at the same time .

Thickness Processing

The thickness of the glass ranges from 2.0mm to 25mm,

Size: 1150*850 1700*1150 1830*2440 1950*2440

Max.3660*2440mm, Other customized sizes are available.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc.

Package And Transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Conclusion

Finally , borosilicates’ excellent electrical insulation properties make them great candidates for complex circuitry designs where insulation between each layer is essential in order prevent short circuits occurring during operation – something that’s especially important when dealing with high voltages which could cause irreversible damage if allowed unchecked currents flowing through sensitive areas on board . All this combines together making borosilicate glass 3.3 an exceptionally suitable solution whenever needing highly durable materials performing reliably under extreme conditions while providing exceptional electrical isolation characteristics too . because these materials don’t suffer from oxidation (rusting) like metal parts do , they’re perfect for long-term reliability in harsh environments where exposure could lead regular metals corroding away over time .