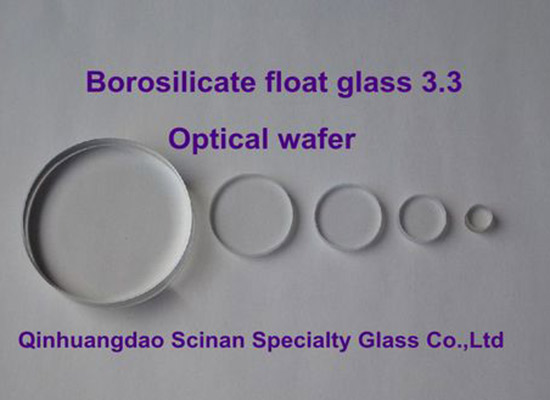

High-Quality Optical Lenses — Borosilicate Float Glass 3.3 Not Only Optimizes Your Vision, But Also Achieves Clarity.

Product Introduction

Borosilicate glass 3.3 is a type of glass that has become increasingly popular in recent years, due to its excellent thermal and chemical resistance properties. It is composed mainly of silica, boric oxide, aluminum oxide, sodium oxide, and other oxides. This specific combination makes it ideal for use in optical lenses as well as various types of laboratory equipment. Borosilicate 3.3 glass can be used as optical lens for cameras and other equipment.At the same time, its wear resistance is also very prominent.

Borosilicate Glass Optical Lenses are used for a variety of applications such as microscopy and telescopes. The combination of the borosilicate glass material with the precision-made optics allows for superior performance when compared to standard plastic or acrylic lenses. Additionally, Borosilicate Glass Optical Lenses provide increased clarity and color fidelity which helps reduce eye fatigue during extended viewing sessions.

Advantages

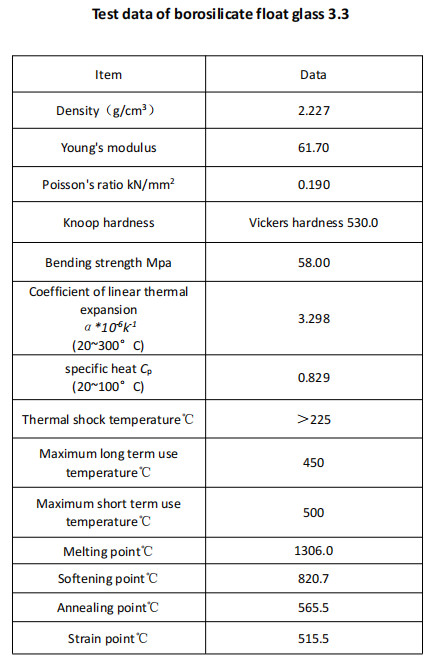

The composition of Borosilicate Glass 3.3 makes it particularly suitable for high temperature use without compromising on strength or durability;

This property can be beneficial when creating optical lenses which require higher temperatures during production processes than what traditional glasses can handle without cracking or melting under pressure.

Characteristics

Low thermal expansion (High thermal shock resistance)

Excellent chemical resistance

Outstanding clarity and ruggedness

Low density

Application field

Borosilicate 3.3 serves as a material of true function and wide applications:

1). Household electrical appliance (panel for oven and fireplace, microwave tray etc.);

2). Environmental engineering and chemical engineering (lining layer of repellence, autoclave of chemical reaction and safety spectacles);

3). Lighting (spotlight and protective glass for jumbo power of floodlight);

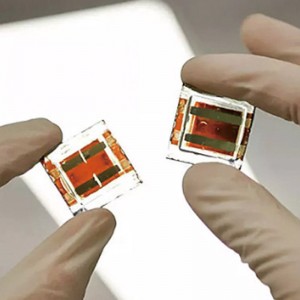

4). Power regeneration by solar energy (solar cell base plate);

5). Fine instruments (optical filter);

6). Semi-conductor technology (LCD disc, display glass);

7). Medical technique and bio-engineering;

8). Safety protection (bullet proof glass

Thickness Processing

The thickness of the glass ranges from 2.0mm to 25mm,

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc.

Package And Transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Conclusion

In conclusion then , Borosilicate Glass 3:3 offers many advantages regarding its usage when making complex optical lenses such as microscopes or telescope components; not only does it have excellent properties against heat distortion but also provides exceptional clarity & colour fidelity necessary when viewing objects at either microscopic level or great distances away respectively – offering users much better visual experiences than many other materials out there today regardless if they’re using them recreationally through hobbyist activities like astronomy/birdwatching etc., professionally through medical research etc., commercial industry related tasks like machine vision monitoring systems utilized in manufacturing operations etc., all the way up into space exploration projects involving robotic probes sent far beyond our solar system boundaries !