Microwave Oven Glass Tray-Borosilicate Glass3.3 That Is Increasingly Popular For Its Excellent Strength And Heat Resistance

Product Introduction

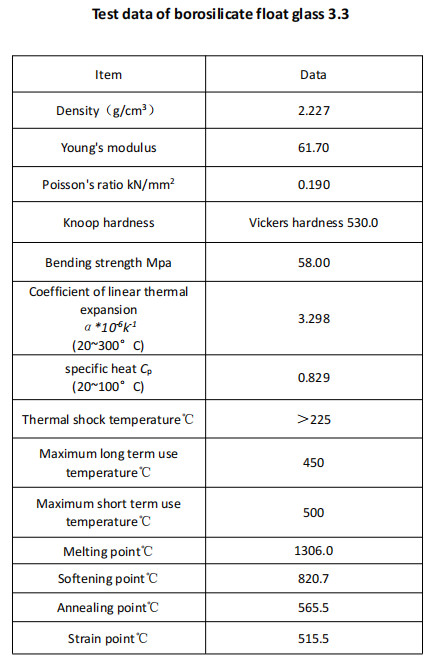

Borosilicate glass3.3 is a type of glass that has become increasingly popular in recent years due to its superior strength and heat resistance. Borosilicate glass oven trays offer an exceptional alternative to traditional metal or ceramic cookware, allowing cooks to achieve the perfect results with their favorite recipes. Borosilicate glass is made from a combination of boron oxide and silica, which give it its increased durability compared to other types of glass. The composition also allows for higher temperature changes without cracking or shattering . This makes it ideal for use in ovens as trays because they won’t warp under high temperatures like other materials would do.

High borosilicate glass is a special glass material with low expansion rate, high hardness, high light transmittance and high chemical stability. Compared with ordinary glass, it has no toxic side effects. Its mechanical properties, thermal stability, water resistance, alkali resistance, acid resistance and other properties are greatly improved, and can be widely used in various fields such as chemical industry, aerospace, military, family, hospital and so on. The expansion coefficient will affect the stability of glass. The expansion coefficient of borosilicate 3.3 heat-resistant glass is 0.4 times that of ordinary glass. Therefore, at high temperature, borosilicate 3.3 heat-resistant glass still maintains excellent stability and will not crack or break.

Advantages

Unlike metal or ceramic trays, borosilicate glass trays are non-porous so there is no risk of food particles becoming lodged within them over time. They also have greater thermal shock resistance than most metals so sudden temperature changes aren’t a problem either – meaning that you can switch between hot and cold environments without any safety concerns associated with such drastic shifts in temperature typically seen with metal pots and pans.

Due to their high quality design, these types of oven trays are incredibly easy to clean as well.

Characteristics

Outstanding thermal resistance

Exceptionally high transparency

High chemical durability

Excellent mechanical strength

Thickness Processing

The thickness of the glass ranges from 2.0mm to 25mm,

Size: 1150*850 1700*1150 1830*2440 1950*2440

Max.3660*2440mm, Other customized sizes are available.

Processing

Pre-cut formats, edge processing, tempering,drilling, coating, etc.

Package And Transport

Minimum order quantity: 2 tons, capacity: 50 tons/day, packing method: wooden case.

Conclusion

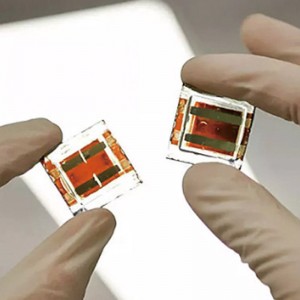

The long-term working temperature of borosilicate 3.3 glass can reach 450 ℃. When used as the glass panel of microwave oven, it can play the role of high temperature resistance. Glass tray turns food to heat evenly. As a component of the microwave oven, the glass tray plays a role of sealing and protection during the operation of the microwave oven.

Finally, one major advantage offered by using borosilicate oven trays instead of traditional metal ones is their aesthetic appeal; this type of material reflects light differently from metallic surfaces which gives dishes cooked in them an extra sparkle when served up on the table – something sure to impress friends and family alike during special occasions!